DLP vs LCD 3D Printer: The Main Differences

DLP vs LCD 3D Printer: The Main Differences

DLP vs LCD 3D Printer: The Main Differences

by Matteo Parenti Updated Jul 22, 2023

If you're considering a DLP vs. LCD 3D printer, it's important to learn what sets them apart. Read on to learn all about their differences!

Resin 3D printing is increasing in popularity, and so are the new and improved technologies in this field. Each year, higher definition models are released alongside more advanced materials, improved firmware and slicing software, and much more. It would be easy to get lost in the ocean of options available, but all of the newest models still share one thing in common: They’re all vat polymerization 3D printers.

Vat polymerization technologies involve a photosensitive resin cured by a light source to produce solid layers and, eventually, whole parts. The layers are the transversal sections of the model, generated beforehand by a slicer program. The resin is contained within a vat, or tank, and is cured against a build platform, which slowly rises out of the tank as the part is formed. The main difference between the three technologies discussed here is the light source. Let’s see what sets them apart.

This technology comes in three main flavors: SLA, DLP, and LCD. It’s common to mix up those names. But with more and more DLP printers approaching the market, it’s important to learn to distinguish them. This article will go over all the similarities and differences between LCD and DLP printers, as well as printers on the market today.

But first, let’s briefly overview the main technologies out there.

DLP vs LCD 3D Printer: The Main Differences

Vat Polymerization

It's all about the vats (Source: All3DP)

While many other technologies involve resins and light sources, we’ll focus on the three most widespread.

SLA

The most well-known and oldest of the three is stereolithography, or SLA for short. It uses a laser, directed by galvanometers, to trace a given layer of a model, curing the resin in its path. Galvanometers can be thought of as mirrors used to guide the laser beam to a particular point in the resin tank.

Throughout the years, the term “SLA printing” has been used as a synonym for resin printing. As we’ll later see, this is only one of the processes that are part of the vast family of resin printing. Hereby, we’ll use the term SLA to refer to this technique only.

DLP

Digital light processing (DLP) uses a digital light projector to cure the resin. It flashes images of complete layers onto the bottom of the vat. Light is selectively directed using a digital micromirror device (DMD), which is a component consisting of hundreds of thousands of tiny mirrors.

Layers generated using DLP printers consist of so-called voxels,the 3D equivalent of pixels. The technology at the core was first invented by Texas Instruments and is the same as a home cinema projector – minus all the methods used to project colors.

LCD

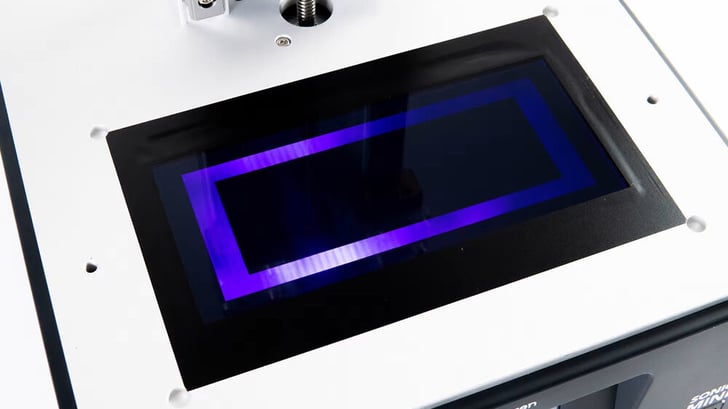

Finally, the most common among hobbyists and makers are liquid-crystal display (LCD) printers. LCD 3D printing is nearly the same as DLP: It also flashes complete layers at the resin tank but with the UV light coming from an array of LEDs shining through an LCD screen, not a projector.

The screen acts as a mask, revealing only the pixels necessary for the current layer and blacking out the rest. This particular technique is often referred to as “Masked SLA”, or MSLA.

Only the unmasked portions of the screen are printed (Source: All3DP)

Other Technologies

It’s always better to look at a 3D printing technology not as a standalone do-it-all process but rather as one piece in the greater puzzle of additive manufacturing. What are other techniques broadly used in this field? The market for 3D printers is immense, so we’ll talk about the two most widespread.

SLS

Select laser sintering (SLS) is similar to the SLA process in many aspects but belongs to the Powder Bed Fusion family of processes. SLS uses a polymer powder instead of a liquid resin. A controlled laser beam fuses the powder together, then a new layer of powder is deposited on top of the previous one.

The main difference with SLA is in the costs and types of material that can be printed. Powders can be made out of metals, too, while SLA can only print polymers.

FDM

Fused deposition modeling (FDM) varies greatly in terms of materials and processes. Instead of a vat, a bed plate is used, and fused material is deposed from the top. For FDM, the material choice is quite vast, including hard polymers, rubberized materials, metals, and high-performance plastics. It usually comes in the form of spools of filament. The low cost and easy learning curve, added to the cheap price of filaments (like PLA), make these machines extremely popular among makers.

DENTwire

DENTwire Exocad

Exocad Roland DGSHAPE

Roland DGSHAPE UP3D

UP3D Bloomden

Bloomden